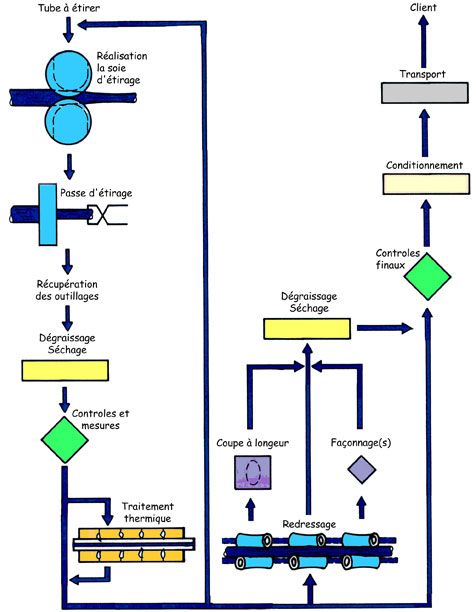

PRODUCTION PROCESS

The principal of cold drawing starts from a blank tube (initial tube) to obtain the required product with diameter and/or thickness smaller than the blank. We talk about drawing operation. The first step of drawing operation is the tube preparation. For this, we realize a drawing tang : this consists in dimensional reduction on one extremity of the tube.

Once this reduction is obtained, the tube pass through a die on a drawing bench. The two methods used by TUBEXACT are cold drawing with mandrel inside the tube and free tube drawing (cf illustration Fig. 1).

Once the drawing operation is done, the toolings are taken back (die and possibly plug) and the tube is degreased. These operations can be renewed as many times as necessary until obtaining final required dimensions. This is important to underline that drawing operation can be implemented on straight lengths or coils. Production with coils reduces the metal loss in a significative way.

|